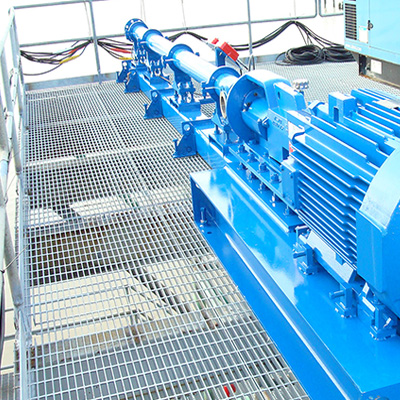

Multistage Surface Pump

The Multistage Surface Pump is a cost-effective, low maintenance H-pump used for high volume and high pressure fluid movement. This horizontal pump includes a field-repairable thrust chamber and a Type 1, balanced Type 1, or cartridge mechanical seal system. Our skid-mounted design allows for convenient, easy installation.

The thrust chamber of the MSP is field-repairable and does not require pump or motor removal for maintenance. It is designed with proven bearing arrangements used in the established Magnum™ I centrifugal pump line. The dual bearing systems provide a minimum L10 life rating of 25,000 hours at all thrust loads up to 20,000 lbf. The standard Mission thrust chamber configuration includes oil level sight glass with an oil temperature gauge. The thrust chamber is specifically designed to handle maximum thrust loads in surface pump operations.

The MSP pump seal system uses standard Type 1, balanced Type 1, or cartridge mechanical seals. The seal face materials are chosen to optimize the seal life according to specific applications. The mechanical seal (located in the fluid end) is completely separated from the thrust chamber which prevents any cross contamination should seal leakage occur. The mechanical seal is field replaceable and can be changed in one hour without disturbing any piping or motor connections.

The modular skid is a universal design that offers significant cost savings and shorter lead times while maintaining motor torque to stabilization requirements. The MSP modular skid was designed using the latest 3D modeling software and finite element analysis tools to ensure a rigid foundation and effective vibration control for extended pump life at the lowest possible cost.

Standard packages include pressure, oil level, and vibration sensors as specified by the customer to meet critical application requirements. Benefits include Low and easy maintenance, Minimal lead time, Cost-effective.