Produced Water Treatment Packages

Maximising hydrocarbon production, while protecting the environment and avoiding discharge penalties requires reliable produced water treatment systems that include desanding and deoiling hydrocyclones, compact flotation units, induced gas flotation, solids cleaning and filtration.

Whether caused by unconsolidated reservoirs, high production rates or the failure of gravel packs and other sand control measures, the effects of sand can be hugely damaging to chokes, flow lines, control valves, pumps and other equipment. Wellhead desanding solutions will help protect critical downstream instrumentation from erosion damage.

Primary Produced Water Treatment like deoiling hydrocyclones enable cleaning produced water with proven, market leading operational performance. The compact nature makes it a high efficiency, high online turndown and high erosion resistance solution that is also extremely cost effective. The deoiling hydrocyclones can be used in new projects or retrofitted into existing systems, where it can be fixed to horizontal or vertical vessels without the need for additional hot work or removal of the vessel, making this system by far the most economical.

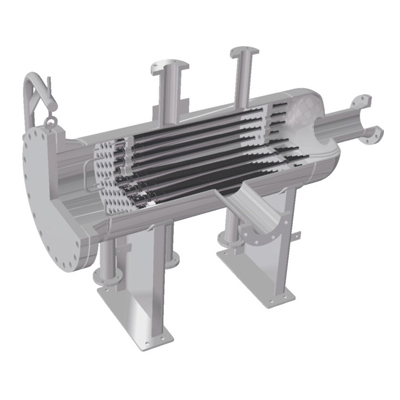

Two and four-cell Induced Gas Flotation (IGF) separators are available to meet all application requirements. IGF reintroduces and incorporates bubbles of gas into the produced water, which adhere to solids and oil before floating to the top of the vessel where they are skimmed off. Chemicals may also be added to the system to improve the adherence of particles and help break down emulsions. For significant process performance on a minimal footprint, our Compact Flotation Units (CFUs) employ the proprietary diffuser swirl device to form a ‘soft spin’ cyclone that creates optimum gas bubble size and distribution for maximum oil recovery. And by using multi-step pressure drop inlet, maximum efficiency can be achieved whilst reducing the need for chemical usage.