Enhanced & Improved Oil Recovery

Flow Improver is a proprietary sub-nano particle formulation from Varichem. It seeks out metal and solid surfaces, attaching itself to them, reduce surface tension. It creates a thin protective membrane layer on pipe/ pump wetted parts/ formation. Specific formulations for treatment of high viscosity oil as in low API oil reservoirs. Field Proven with several dozen wells successfully treated

As a result of the sheathing by the Flow Improver, corrosion of metal parts like pipes and pump is mitigated and improves lubricity of the entire system. Flow Improver is environmentally safe, does not alter the crude oil chemistry and has no adverse effect on materials including metals or elastomers

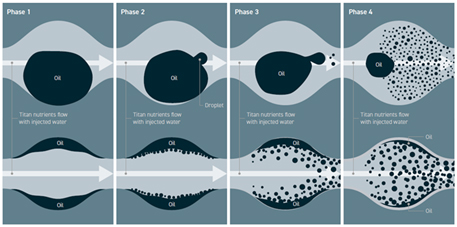

The Nano-Surfactant EOR technology is powered by a proprietary chemical with increased electron potential. The chemistry involved forms an extremely concentrated alkali product that results in a femto scale molecular structure that affects the attraction and repulsion of hydrocarbons to mineral surfaces.

Once the mineral surfaces are exposed to the Nano-Surfactant chemistry, the surface becomes much less attractive to oil which then allows the oil to move. The natural tendency is for the technology to penetrate the formation pour space, break the hydrogen bonding and surface tension that traps the oil and then physically displace the oil from the space. It continues to penetrate deeper and further into the formation until the electronic exchange is exhausted.

The Nano-Surfactant EOR technology is highly concentrated and saturated with excess OH groups. In the oil-bearing formations, the chemical formulations readily seek to disrupt weak hydrogen bonding that are associated with crude trapped in the formation pours. The chemistry is water soluble which causes rapid dispersion as it readily moves through the near well bore area and formation. This creates added value since no additional pressure is required for it to migrate deeper into the fracture network where no other stimulant chemicals have gone before.