Well Completion & Wellhead Solutions

Complete suite of well Completions Accessories to customize well completions and mitigate risk for the life of the well. Our products resolve issues related to tubing movement, scale buildup, corrosion, erosion, selective production, zonal isolation, intelligent completions, and more. This includes, but not limited to:

- Seating & Landing Nipples

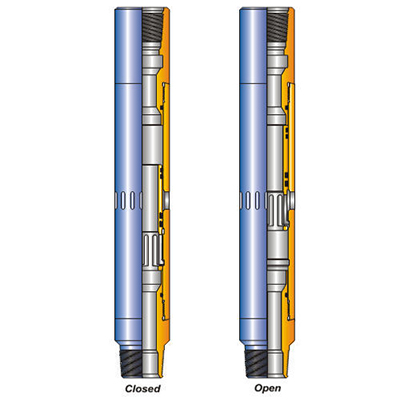

- Sliding Sleeves

- Temporary Tubing Plugs

- Chemical Injection Mandrels

- Adjustable Union & Joint

- Expansion & Slip Joints

- Blanking & Circulating Plugs, Standing Valves

- Miscellaneous Completion Accessories

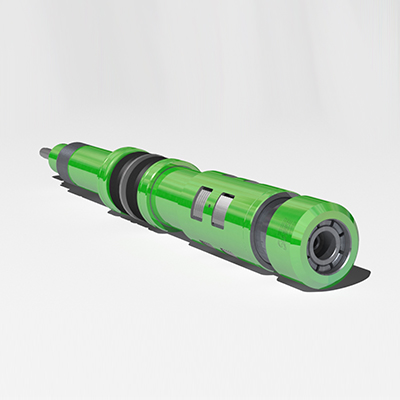

Packers systems are among the most important tools in the tubing string. Packers systems and associated tools enable flow from or injection into the formation to or from the tubing string in an efficient way without restricting normal production or injection flow. The types of packer systems vary greatly in terms of application, size, configuration, etc. The selection will depend upon specific wellbore and reservoir condition. The primary classification of packers is based on whether it is Retrievable or Permanent. Within this packer types can be based on the method of conveyance, being run and set on the production tubing string or inside the tubing.

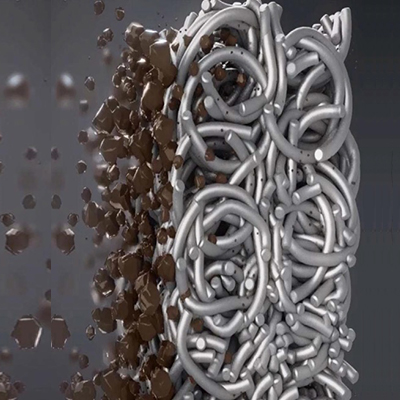

Permeable Matrix (PM) Filter system comprises of wire coils formed into a flexible matrix by cold plastic deformation with no welding or brazing. The unique design and manufacturing process enables flexible, porous filtration in all directions, allowing flow from outside to inside the artificial lift pump inlet or production tubing, as applicable. The elastic deformation during flow and return to original shape during no flow enables knocking off particles sticking to the filter exterior. PM filters have 3D slotted channels and capable to filter out particle sizes as small as 3 microns. It has over 4 times more flow area than traditional Wedge wire screens, lower hydraulic resistance and lower pressure drop. PM filters have high resistance to erosion and effective in aggressive and sour environment, robust and resistant to mechanical damage. Other features of PM filter technology include; The PM downhole filter technology has enabled increased MTBF in ESP and Rod pumps by order of 2 to over 10 times as compared to conventional wedge wire screen filters.

- Use in very high temperatures of the order of 300 degC. Application in steam wells.

- Ability to regenerate. Recovery of up to 90% filtering properties

- Track record of installations in over 1000 wells

- Run with completion, it is a good alternative to gravel packs, WWS, etc….

OCTG is family of seamless rolled products consisting of drill pipe, casing and tubing subjected to loading conditions according to their specific application. Drill pipe is heavy seamless tube that rotates the drill bit and circulates drilling fluid. Pipe segments 30 ft (9m) long are coupled with tool joints. Drill pipe is simultaneously subjected to high torque by drilling, axial tension by its dead weight, and internal pressure by purging of drilling fluid.

Casing pipe lines the borehole. It is subject to axial tension by its dead weight, internal pressure by fluid purging, and external pressure by surrounding rock formations. Casing is particularly exposed to axial tension and internal pressure by the pumped oil or gas emulsion.

Tubing is pipe through which the oil or gas is transported from the wellbore. Tubing segments are generally around 30 ft [9 m] long with a threaded connection on each end.