Well Stimulation & Production Enhancement

Oil Safe AR is a state-of-the-art, patented technology in green oilfield treatment alternative. Living up to its namesake, this hydrochloric acid replacement is 100% environmentally sound, giving our client’s a competitive edge, where and when it is needed most. The performance driven blend makes this oilfield treatment as effective as it is eco-friendly.

Oil Safe AR® is manufactured with products chosen from the EPA’s Design for the Environment “Safe Chemical Ingredients List” that meet the criteria for Design for the Environment Safer Product Program. It is non-regulated by US D.O.T. and carries a triple zero hazardous materials information system score. Oil Safe AR® biodegrades in 10 days or less and is manufactured with ingredients set forth by the US EPA Design.

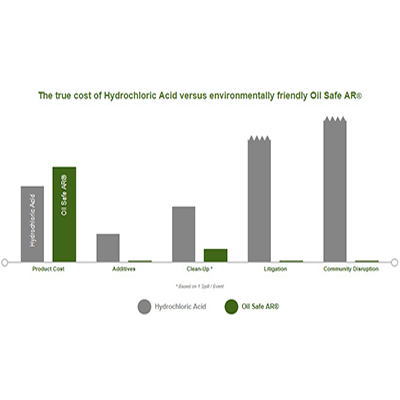

While the oil industry has traditionally used hydrochloric acid as a cost-effective oilfield treatment, the true expense of this harmful chemical is realized by companies during a single spill. Hydrochloric acid spills not only leave behind the destruction of entire communities, the public relations effect on a company’s name often has devastating consequences.

The F-100 from VariChem is a foaming acid soapstick used to clean calcium and iron deposits from perforations in disposal wells and oil and gas producing wells. Regular use in wells that tend to plug with iron oxides, sulfides, and calcium salts will prevent expensive shutting down. On a scale of 1-10 this sticks hardness is 9.

Innovative fluid solution that can help greatly improve production from heavy oil wells with high viscosity. The Flow Improver is a proprietary chemistry formulation from Varichem that attaches to the formation forcing imbibed oil to release. The Flow Improver also attaches to metal parts like production tubing and artificial lift pump, protecting it from corrosion and improves lubricity of the entire system.

Flow Improver is very versatile allowing to be used in many different applications. The sub-nano technology functions much like a nano particles but without Brownian motion. It is environmentally Safe and also has no adverse effect on pump materials including elastomers

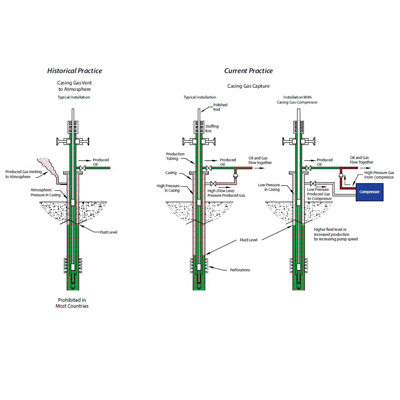

Weak (low pressure) gas wells are severally impacted by the backpressure from the flowline and production facility. The well will eventually stop continous flow and production will be cyclic, unless some form of external energy is provided. One such means of external energy is Wellhead compression, which is hooked up into the flowline. This will help to lower the back pressure on the well by upto 375 psi which will enable the well to produce at revert back to continous production and thus enable higher gas rate.

The same gas compression technology can also be used for oil wells running on sucker rod pump or PCP. The annulus is normally connected to the flowline whose pressure would permeate to the well formation and impede production. By hooking up the casing gas compressor system to the well annulus, the flowing bottomhole pressure can be reduced and thus inflow into the well and thus the production can be increased.