Artificial Lift Systems

Artificial lift refers to methodology of producing fluids from a well to surface once the well is no longer capable of producing by itself. Artificial lift is needed in wells when there is insufficient pressure in the reservoir to lift the produced fluids to the surface, but can also be used in naturally flowing wells to increase the flow rate above what can produce through natural flow.

PSC Technologies provides a host of Artificial Lift solutions as covered in this section.

- Hydraulic Jet Pump

- GasLift Systems

- Supersonic Pump

- Plunger Lift

- Hydraulic Long Stroke Steel Cable Pumps

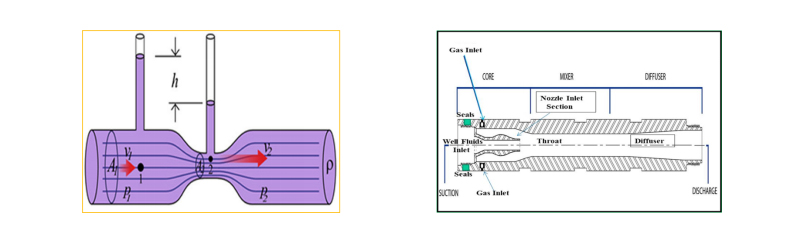

A Hydraulic Jet Pump system involves a surface pump that injects a power fluid down the tubing into the downhole Jet Pump. By utilizing the Venturi effect, the formation fluid is drawn into the pump, commingles with the power fluid and returns to the surface. With No Moving Parts Downhole, the Jet Pump System is the most attractive solution to operators working in unique situations where dependable, efficient and cost effective artificial lifting needs are required. Applications of Jet Pump system apart from Artificial Lift include

- Accelerated Frac Flowback

- Gas Wells Dewaterin

- Drill Stem Testing

- Production – Up to 4500 bpd

- Can be run on 1-1/4″ IJ or Coil Tubing to over 3-1/2” tubing or larger

- Can be run inside casing 5.0 and up

- Special 3 coat hardening process for erosion and corrosion control (On all pumps)

- Produces wells with extremely high solids content

- Produces extremely high volume wells

- Can be retrieved by reverse circulation or wire line

A gas lift system consists of compressed gas being injected through gas lift mandrels and valves into the production string. The injected gas lowers the hydrostatic pressure in the production string to establish the required pressure differential between the reservoir and wellbore, and causing the formation fluids to flow to the surface.

- High degree of flexibility and design rates

- Excellent sand handling capability

- Minimal amount of surface requirements

- Minimal moving parts

- Full bore drift of tubing

- Wireline retrievable

- Wells with insufficient bottomhole pressures or

- Deep wells with large hydrostatic head and unable to flow by itself

- Readily available high pressure injection gas near well

- Kick off wells for natural flow by clearing the heavier completion fluids from tubing

- Unload water from gas wells that would otherwise prevent gas production

- Continuous or intermittent flow

The Supersonic Pump (SSP) is an innovative development in the field of Artificial Lift. It combines the benefits of gas lifting and Ejector pumps, decreasing the fluid column density and accelerating fluid to supersonic velocities generating suction below the jet. This enables additional fluid inflow into the wellbore and thus resulting in increased well production.

SSP does not have any moving parts and hence low on maintenance costs. The SSP is Ideal for GL wells with available provision for gas injection. It is adaptable to different tubing sizes, flow rates and fluid phases. Installation of SSP can be carried out without hoist by using standard wireline units.

Plunger Lift is the most cost effective form of artificial lift that uses the well’s natural energy. It is suitable for number of applications and can be used for both oil and gas wells. It offers excellent corrosion and gas handling, this system provides optimum solutions for production enhancement, particularly in high gas-to-liquid ratio wells.

Plunger systems are easy to maintain, well suited for small fields, marginal well and remote wells. Principal hardware in a Plunger Lift system include the plunger, downhole bumper spring assembly, surface lubricators, System controllers, Control valve and accessories.

Compared to the traditional Beam pump units, the Non-conventional Rod pump Surface drive system have several advantages like lesser tubing and sucker rod wear, Fewer well interventions, Higher downhole pump compressions. Customers have reported higher than 85% pump efficiency in gassy wells. There are no large rotating counterweights in an effort to maximize safety. Installations can be completed within very short time as low as within 4 hours. Integrated Pump Off Controller comes as a standard. Options for SCADA ready via proven Remote Monitoring System available to enable remote access from the comfort of office. All parameters can be adjusted via touch screen including speed and stroke length. Steel Cable replace Sucker Rods